MACH-ProAir

BACnet® Controller

Engineered to exceed the specifications for a wide variety of Variable Air Volume (VAV) applications, the Reliable Controls® MACH-ProAir is a fully programmable BACnet Building Controller (B-BC) with numerous downloadable standard codes and flexible I/O options, all priced to meet a modest budget.

Features

Dynamic Database

- Shared memory allows creation of supported objects as required (up to memory max, or 128 object limit, whichever is reached first)

- All models provide 32K of database memory and 28K of trend memory

- Typical Object Configuration table shown below

Protocol

- BACnet® - MS/TP (EIA-485)

Motor Control

- Standard VAV and optimized motor control algorithms stored in firmware

- Numerous standard application codes can be downloaded from the Reliable Controls®website

- Optional user-programmed algorithm

Engineered Enhancements

- Onboard End Of Line (EOL) switch with LED indication provides easy EOL configuration and visual verification

- Remote addressing and software selectable inputs allow detailed configuration to be completed over the network

- Robust MRAM non-volatile memory preserves trend data on power cycle

- BACnet COV support provides optimized network sharing

Control-BASIC™ Programs

- 8500 bytes programmable control strategy in a readable, BASIC-like language

- 3200 bytes per program

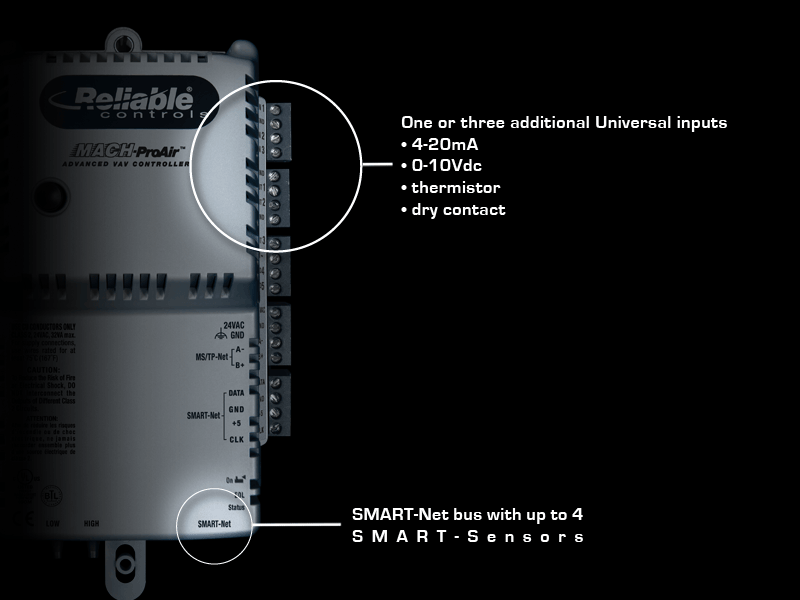

Inputs

- Universal ranges

- Soft-selectable 0-10 VDC, 4-20 mA, thermistor / dry contact

Outputs

- Universal ranges

- 0-12 VDC or TRIAC, model dependent

Variables

- Selectable standard and custom ranges, as well as fixed or program-driven values

PID Loops

- Standard P, PI, or PID controllers for closed loop control

Single-Point Trend Logs

- Samples created at polled, COV, or triggered intervals

- Default 128 samples, configurable to allow trending over a longer period of time

Multipoint Trend Logs

- Each Trend Log includes 8 points at polled or triggered intervals

- Default 128 samples, configurable to allow trending over a longer period of time

Runtime Report

- Records the total On time and the total number of transitions, as well as daily transitions for every binary point

- A 50-sample runtime log is optional for each binary point

System Groups

- Allows related points to be grouped onto one display

- 80 points/group

Schedules

- 7 On/Off times for each weekday or exception

Calendars

- Days of the year designated as holidays

Arrays

- Up to 128 elements in a one-dimensional array

Tables

- For creating custom input ranges and Control-BASIC™ lookup tables

Custom Units

- 8 analog engineering units

- 8 binary engineering units

- 8 multistate units with 8 states, 32-characters each

SMART-Net™ Port

- Networks up to 4 SMART-Sensors™

32 Network In Points

16 Network Out Points

- The total maximum number of writes and shares to other devices

Warranty

- 5 years

Certification

- BTL Listed (B-BC)

- UL916 Listed

- CFR47 Part 15/B

- CE

Typical Object Configuration

There are physical limitations to the number of inputs, outputs, and SMART-Sensors that can be connected to a MACH-ProAir. For other object types, there are no imposed limits for the maximum number of objects of a single type. The main constraint for created objects is onboard memory, however, the total number of objects that can be created (including inputs, outputs, and SMART-Sensors) is limited to 128. The table below details a typical database that fits in the memory module for any model.

Variables (48) Loops (4) Schedules (2) Calendars (1) Tables* (2) Groups (2) Multipoint Trend** (2) Runtime* (32) Arrays (2) Program (8) SMART-Sensor*** (4)

* Tables and Runtime Logs are not counted in the 128 object limit. Inputs, outputs, and the device object are counted in the 128 object limit.

** Trends are configured to store 128 samples.

*** All models accommodate a maximum of 4 SMART-Sensors.

Tech Specs

Processor & Memory

- 66 MHz, high-performance, 32-bit embedded microcontroller with onboard Flash memory

- Controller database, values, log data, and configuration held in robust non-volatile memory

- Operating System firmware easily updated at any time over the network

Supply Voltages

- 24 VAC ±10% 32 VA max. 50/60 Hz

- 24 VDC ±10% 12 W max.

Note: MPA-12 and MPA-111 require 24 VAC only to support internal power to TRIACs

Communications

- MS/TP

- EIA-485 @ 76.8 Kbps max.

- Auto-baud detection

- SMART-Net™

- 4 SMART-Sensors™ max.

- RJ-11 port on all models

- 4 wire terminal connector on all models

Universal Inputs

- 12-bit A/D converter

- Soft selectable: 0-10 VDC, 4-20 mA,

thermistor/dry contact - Impedance:

3M Ω on 0-10 VDC range

250 Ω on 4-20 mA range

20k Ω on thermistor range - Pulse counting up to 40 Hz

(supports flow meters) - 24 VAC over-voltage protection

Universal Outputs

- 10-bit D/A converter

- Analog: 0-12 VDC

- Binary: 0/12 VDC

- Output power: 75 mA @ 12 VDC

- 24 VAC over-voltage and short protection

TRIAC Outputs

- 24 VAC @ 0.5 A

SETUP-Tool™

- SETUP-Tool™ optional for MS/TP configuration

Dimensions

- With actuator:

22.7 cm L x 10.1 cm W x 7.7 cm H

(8 15/16" L x 3 15/16" W x 3" H) - Without actuator:

19.9 cm L x 10.1 cm W x 7.3 cm H

(7 13/16" L x 3 15/16" W x 2 7/8" H) - With MPA-C:

22.7 cm L x 15.0 cm W x 7.7 cm H

(8 15/16" L x 5 7/8" W x 3" H)

Mounting

- Supplied with #8 screw

- Compatible with 3/8" to 1/2" damper blade shaft

Weight

- 0.7 kg (1.8 lb.)

Ambient Limits

- Operating: 0 ºC to 50 ºC (32 ºF to 122 ºF)

- Shipping: -40 ºC to 60 ºC (-40 ºF to 140 ºF)

- Humidity: 10% to 90% RH non-condensing

Velocity Sensor

- ±0-500 Pa (0-2" WC)

- Maximum zero point accuracy 0.1 Pa (0.0008" WC)

- Resolution: 0.122 Pa (0.0005" WC)

- Span accuracy 3% of reading

Actuator

- Torque 45 in-lb (5 Nm)

- Brushless D.C.

Flow Sensor

- 5.2mm OD barbed fittings

- Suitable for 1/4" standard pneumatic control tubing

Enclosure

- ABS

- UL94-5V